Forged ring body have choose special alloy steel forging and High Strength Quenched and tempered after treatment. It has superior mechanical property.

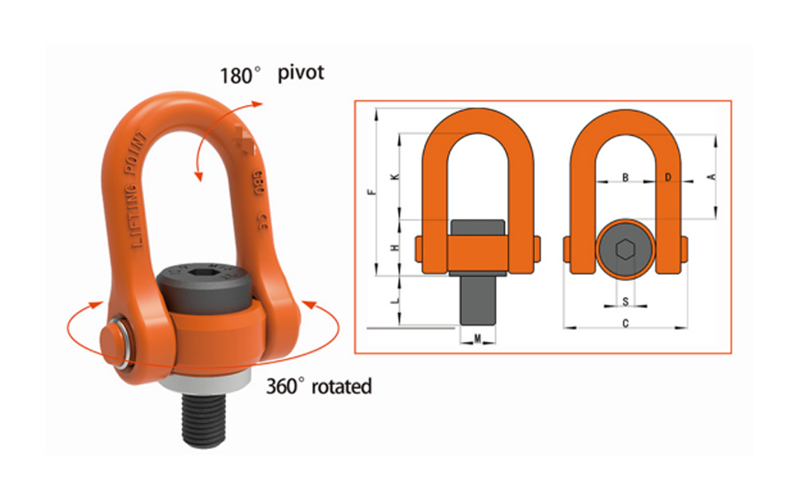

It can be adjustable as different force direction and force angles. Point to rotate around the axis are 180". Equal tensile force WLL on different direction and have 4 times safety factor.

Available on demand for WLL range (M8 M48) choose of standard metric thread, metric fine thread, UNC, UNF thread, BSW(British standard Whitwroth thread)and so on. Multiple bolt lengths available to meet specific application requirement for long or through hole.

| NO. | WLL/T | Thread/M | Diamensions/mm | Nm | WEIGHT(kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | A | B | C | D | F | K | H | S | |||||

| -M8 | 0.5 | M8×1.25-6g | 12 | 50.5 | 37 | 76 | 14 | 101.5 | 49.5 | 38 | 8 | 30 | 0.8 |

| -M10 | 0.7 | M10×1.5-6g | 16 | 50.5 | 37 | 76 | 14 | 101.5 | 49.5 | 38 | 8 | 60 | 0.8 |

| -M12 | 1 | M12×1.75-6g | 18 | 50.5 | 37 | 76 | 14 | 101.5 | 49.5 | 38 | 8 | 100 | 0.8 |

| -M14 | 1.5 | M14×2.0-6g | 21 | 50.5 | 37 | 76 | 14 | 101.5 | 49.5 | 38 | 8 | 120 | 0.8 |

| -M16 | 2 | M16×2.0-6g | 24 | 50.5 | 37 | 76 | 14 | 101.5 | 49.5 | 38 | 8 | 150 | 0.8 |

| -M18 | 2.5 | M18×2.5-6g | 40 | 73 | 54 | 106 | 20 | 145 | 77 | 48 | 12 | 200 | 1.9 |

| -M20 | 3 | M20×2.5-6g | 40 | 73 | 54 | 106 | 20 | 145 | 77 | 48 | 12 | 250 | 2 |

| -M22 | 3 | M22×2.5-6g | 40 | 73 | 54 | 106 | 20 | 145 | 77 | 48 | 12 | 250 | 2.1 |

| -M24 | 4.5 | M24×3.0-6g | 40 | 73 | 54 | 106 | 20 | 145 | 77 | 48 | 12 | 400 | 2.5 |

| -M27B | 5 | M27×3.0-6g | 40 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 450 | 5.5 |

| -M30 | 7.3 | M30×3.5-6g | 45 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 500 | 5.5 |

| -M33 | 8 | M33×3.5-6g | 50 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 800 | 5.5 |

| -M36 | 10 | M36×4.0-6g | 54 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 1000 | 5.5 |

| -M39 | 10 | M39×4.0-6g | 58 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 1200 | 6 |

| -M42 | 12.5 | M42×4.5-6g | 63 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 1500 | 6 |

| -M45 | 15 | M45×4.5-6g | 63 | 98.5 | 73 | 149 | 30 | 201.5 | 103.5 | 68 | 17 | 1800 | 6 |

| -M48S | 16 | M48×5.0-6g | 63 | 98.5 | 73 | 149 | 30 | 201.5 | 101.5 | 70 | 17 | 2000 | 6.5 |

| -M48B | 20 | M48×5.0-6g | 68 | 120 | 93 | 182 | 36 | 249 | 125 | 84 | 19 | 2000 | 11.5 |

| -M52 | 20 | M52×5.0-6g | 68 | 120 | 93 | 182 | 36 | 249 | 125 | 84 | 19 | 2000 | 12 |

| -M56 | 25 | M56×5.5-6g | 78 | 120 | 93 | 182 | 36 | 249 | 125 | 84 | 19 | 2100 | 12 |

| -M64 | 32 | M64×6.0-6g | 90 | 120 | 93 | 182 | 36 | 252 | 125 | 88 | 19 | 2200 | 13 |