Integral die forging Lifting point made of special alloy steel with precision forging,it had high mechanical performance after special heat treatment process.

Integral die forging Lifting point made of special alloy steel with precision forging,it had high mechanical performance after special heat treatment process.

Working tensile is the same in any direction, safety factor 4:1.

The surface is coated with epoxy resin, which prevent surface corrosion effectively.

Different kinds of thread are available, wide range of WLL load(M8-M1 50,0.3T-50T);the available thread including:Metric thread, Metric fine thread, UNC thread,UNF thread,BSW thread and So on.

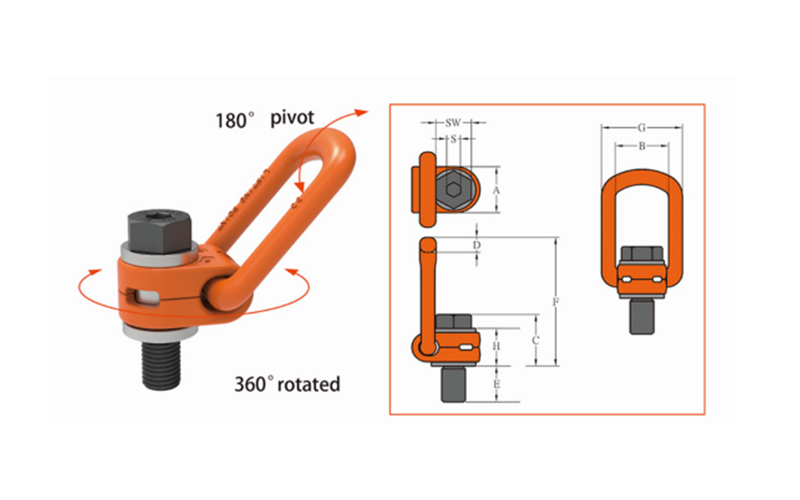

| NO. | WLL/T | M | Diamensions/mm | Nm | WEIGHT(kg) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E | A | B | C | D | F | G | H | S | SW | |||||

| -M8 | 0.3 | M8×1.25-6g | 11 | 34 | 37 | 42 | 14 | 98.5 | 57 | 36 | 6 | 13 | 30 | 0.5 |

| -M10 | 0.63 | M10×1.5-6g | 16 | 34 | 37 | 43 | 14 | 98.5 | 57 | 36 | 6 | 16 | 60 | 0.5 |

| -M12 | 1 | M12×1.75-6g | 18 | 34 | 37 | 45 | 14 | 98.5 | 57 | 36 | 8 | 18 | 100 | 0.5 |

| -M14 | 1.2 | M14×2.0-6g | 21 | 34 | 37 | 46 | 14 | 98.5 | 57 | 36 | 10 | 21 | 120 | 0.5 |

| -M16 | 1.5 | M16×2.0-6g | 24 | 34 | 37 | 48 | 14 | 98.5 | 57 | 36 | 10 | 24 | 150 | 0.5 |

| -M18 | 2 | M18×2.5-6g | 26 | 50 | 54 | 57 | 16.5 | 143 | 82 | 44 | 12 | 27 | 200 | 1.5 |

| -M20 | 2.5 | M20×2.5-6g | 30 | 50 | 54 | 58 | 16.5 | 143 | 82 | 44 | 12 | 30 | 250 | 1.5 |

| -M22 | 3 | M22×2.5-6g | 30 | 50 | 54 | 60 | 16.5 | 143 | 82 | 44 | 12 | 34 | 300 | 1.5 |

| -M24 | 4 | M24×3.0-6g | 36 | 50 | 54 | 61 | 16.5 | 143 | 82 | 44 | 14 | 36 | 400 | 1.5 |

| -M27 | 4 | M27×3.0-6g | 38 | 60 | 65 | 80 | 22 | 170 | 99 | 62 | 17 | 41 | 400 | 3 |

| -M30 | 5 | M30×3.5-6g | 48 | 60 | 65 | 82 | 22 | 170 | 99 | 62 | 17 | 46 | 500 | 3.5 |

| -M33 | 6 | M33×3.5-6g | 54 | 60 | 65 | 85 | 22 | 174 | 99 | 60 | 22 | 55 | 600 | 3.5 |

| -M36S | 7 | M36×4.0-6g | 54 | 60 | 65 | 85 | 22 | 174 | 99 | 60 | 22 | 55 | 700 | 3.5 |

| -M36B | 8 | M36×4.0-6g | 62 | 77 | 85 | 104 | 27 | 226.5 | 123 | 79 | 22 | 55 | 800 | 6 |

| -M39 | 8 | M39×4.0-6g | 62 | 77 | 85 | 104 | 27 | 226.5 | 123 | 79 | 22 | 55 | 800 | 6 |

| -M42S | 10 | M42×4.5-6g | 72 | 77 | 85 | 106 | 27 | 226.5 | 123 | 79 | 22 | 65 | 1000 | 6.5 |

| -M42B | 15 | M42×4.5-6g | 63 | 95 | 104 | 117 | 36 | 226.5 | 158 | 90 | 22 | 65 | 1500 | 11 |

| -M45 | 15 | M45×4.5-6g | 63 | 95 | 104 | 117 | 36 | 257.5 | 158 | 90 | 22 | 65 | 1600 | 11 |

| -M48 | 20 | M48×5.0-6g | 72 | 95 | 104 | 120 | 36 | 257.5 | 158 | 90 | 27 | 75 | 2000 | 12 |

| -M52 | 20 | M52×5.0-6g | 72 | 95 | 104 | 120 | 36 | 257.5 | 158 | 90 | 27 | 75 | 2000 | 12 |

| -M56 | 22 | M56×5.5-6g | 84 | 95 | 104 | 117 | 36 | 257.5 | 158 | 90 | 27 | 85 | 2100 | 15 |

| -M64 | 22.5 | M64×6.0-6g | 100 | 114 | 104 | 138 | 36 | 264.5 | 158 | 103 | 32 | 95 | 2200 | 16.3 |